In addition to the function of DRF-2 plasma cladding equipment, DRF-5B equipment can be used for plasma cladding on the sealing plate of large middle trough and the inner wall of pipeline to improve its wear resistance.

Power | Inverter Plasma Power Supply |

Input Voltage | 380±10% |

Rated Input Capacity | 30KVA |

Rated Load Sustained Rate | 100%(20℃) |

Rated Cladding Current | 300 Amperes |

No-load Voltage | 140VDC |

Working Voltage | 50VDC |

Cladding Speed Adjustment Range | 100~1000mm/min |

Route | 1300×1700×700mm |

Argon Consumption | 1.5m3/h |

Floor Area | 3000×2100×2500mm |

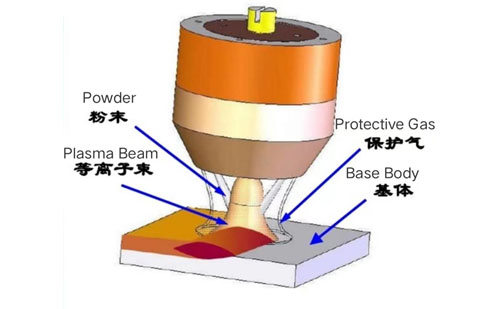

Schematic Diagram of Synchronous Injection of Powder and Plasma Beam

● Form annular negative pressure plasma beam, reduce the velocity difference of the powder material in the plasma jet, and reduce the powder loss.

● The pressure equalizing ring groove is around the plasma generator nozzle to obtain flexible plasma beam, reduce scouring force, prevent alloy oxidation, and stabilize arc column.

Basic Principle:

Under the action of high temperature plasma beam, the alloy powder and the workpiece surface are rapidly heated and melted together, mixing, diffusion, reaction, solidification; self-cooling after the plasma beam leaves, the high hardness wear-resisting layer is formed over the surface, so as to realize the surface strengthening and hardening, and enhance the wear resistance of the workpiece. The wear-resisting layer of plasma cladding not only has high hardness, but also will not fall off under impact load, due to metallurgical bonding between the wear-resisting layer and the workpiece matrix.

We offer an extensive range of conveyor belt vulcanization joint machine, conveyor belt repair machine & electric pickling machine that are perfectly suited for a variety of mining machine operating environments