The difference between plasma cladding equipment and traditional surface treatment technology

ⅠPrinciple of Equipment

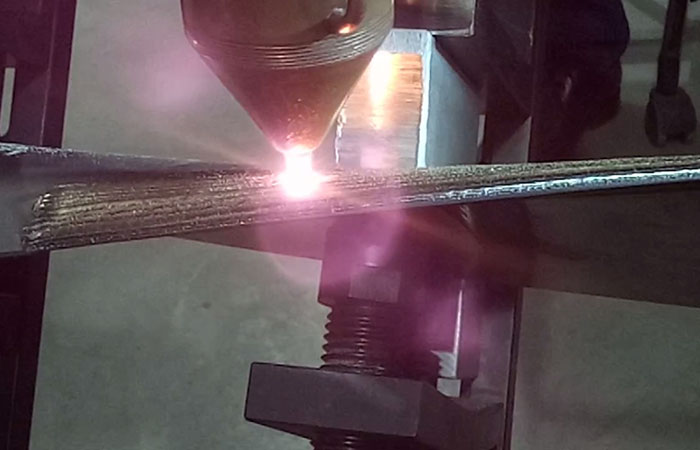

Plasma cladding devices use the high temperatures generated by plasma arcs to melt metal powders, ceramic powders, or other materials and quickly cool to form a strong coating. The traditional surface treatment technology uses electroplating, spraying, thermal spraying and other methods to attach materials to the surface of the workpiece.

ⅡEquipment Advantages and Disadvantages

The advantages of plasma cladding equipment include: good metallurgical bonding between coating and substrate, wide selection of coating materials, controllable coating thickness, high production efficiency, stable coating quality and so on. However, its disadvantages are also more obvious, such as large equipment investment, high maintenance costs, and high requirements for operator skills.

The advantages of traditional surface treatment technology mainly include: mature process, simple operation and low cost. However, its disadvantages are also more obvious, such as weak binding force between the coating and the substrate, difficult to control the thickness of the coating, and low production efficiency.

Ⅲ Technology Application

Plasma cladding technology has been widely used in petrochemical industry, machinery manufacturing, aerospace and other fields. For example, in the petrochemical industry, plasma cladding technology can be used to manufacture equipment such as wear-resistant and corrosion-resistant valves, pipes and reactors. In the traditional surface treatment technology application fields, such as automobile manufacturing, electronics industry, etc., its application is still very wide.

Ⅳ Future Outlook

With the continuous development of science and technology, plasma cladding technology will be more mature and perfect. Future research directions mainly include: improving the binding force between coating and substrate, developing new coating materials, optimizing equipment structure and process parameters, and improving production efficiency. At the same time, with the continuous improvement of environmental awareness, traditional surface treatment technology will gradually be replaced by environmentally friendly surface treatment technology.

To sum up, plasma cladding equipment and traditional surface treatment technology have advantages and disadvantages, and appropriate surface treatment technology should be selected according to specific application scenarios and needs. In the future, with the continuous development of science and technology, surface treatment technology will also continue to improve and improve, and make greater contributions to industrial development and social progress.