The equipment can be used for plasma cladding strengthening towards the sprocket of the scraper conveyor, the drum of the tunnel boring machine and the shearer, the bucket teeth of the excavator and other parts with irregular shape, as well as the parts with limited operating space such as the central groove side steel, so as to improve its wear resistance and prolong its service life. The equipment can be widely used in mining, steel, cement and other industries that urgently need to greatly improve the wear resistance of parts.

| Power | Inverter Plasma Power Supply |

| Input Voltage | 380±10% |

| Rated Input Capacity | 15KVA |

| Rated Load Sustained Rate | 100%(20℃) |

| Rated Cladding Current | 220 Amperes |

| No-load Voltage | 140VDC |

| Working Voltage | 40VDC |

| Cladding Speed Adjustment Range | - |

| Route | - |

| Argon Consumption | 1.5m3/h |

| Floor Area | 1600×900×1100mm |

| Machine Weight | About 330KG |

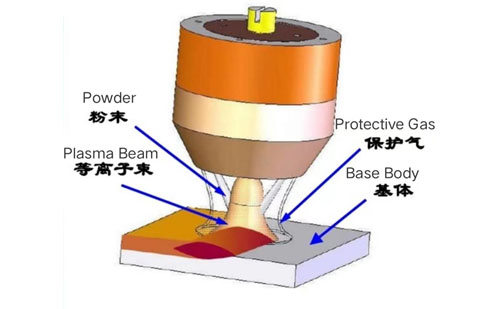

Schematic Diagram of Synchronous Injection of Powder and Plasma Beam

● Form annular negative pressure plasma beam, reduce the velocity difference of the powder material in the plasma jet, and reduce the powder loss.

● The pressure equalizing ring groove is around the plasma generator nozzle to obtain flexible plasma beam, reduce scouring force, prevent alloy oxidation, and stabilize arc column.

Basic Principle:

Under the action of high temperature plasma beam, the alloy powder and the workpiece surface are rapidly heated and melted together, mixing, diffusion, reaction, solidification; self-cooling after the plasma beam leaves, the high hardness wear-resisting layer is formed over the surface, so as to realize the surface strengthening and hardening, and enhance the wear resistance of the workpiece. The wear-resisting layer of plasma cladding not only has high hardness, but also will not fall off under impact load, due to metallurgical bonding between the wear-resisting layer and the workpiece matrix.

We offer an extensive range of conveyor belt vulcanization joint machine, conveyor belt repair machine & electric pickling machine that are perfectly suited for a variety of mining machine operating environments